Basic Principles and Application of the Vibration Technology

Fig. 1: Partial view of a truss shuttering [45m]

Fig. 1: Partial view of a truss shuttering [45m] with high frequency external vibrators

Concrete is poured into moulds and vibrated to let the trapped air escape and so to compact it. Before hot chocolate is poured into its form, vibration technology is used to deaerate the liquid. The objectionable air pockets disappear when the vibration stirs up the material and the friction between the individual particles of the material is decreased. The material becomes loose and flows off properly.

Even bulk materials like sand, cement, lime, coal, cereals, etc. which are stored in silos or other containers have to be set to motion to overcome the powerful adhesive forces, reduce the friction between the individual particles, and thus to support the outflow. Furthermore the motion of material is necessary for conveying of the bulk materials on conveyor troughs and sieving on reciprocating screens. This motion is created by so-called external vibrators, which are attached to vibrating equipments, chute of silos, or conveying throughs.

Design of External Vibrators

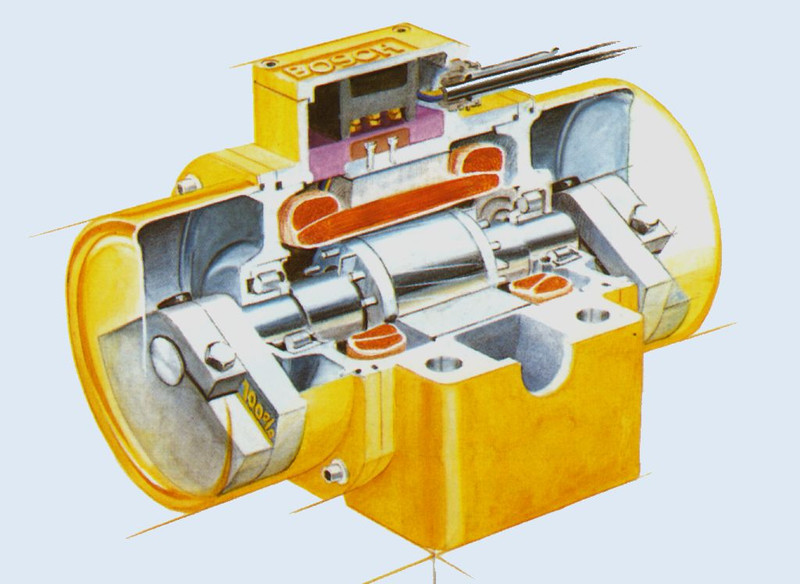

Fig. 2 Cut view of an external vibrator with a three-phase asynchronous motor

Fig. 2 Cut view of an external vibrator with a three-phase asynchronous motor

The external vibrator is a three-phase asynchronous motor. So-called eccentric weights (discs) are fixed eccentrically at the ends of the rotor shaft. At rotating, centrifugal forces are generated. These forces can be adjusted by moving the discs at standstill. The discs are divided so that the centrifugal force can be easily regulated.

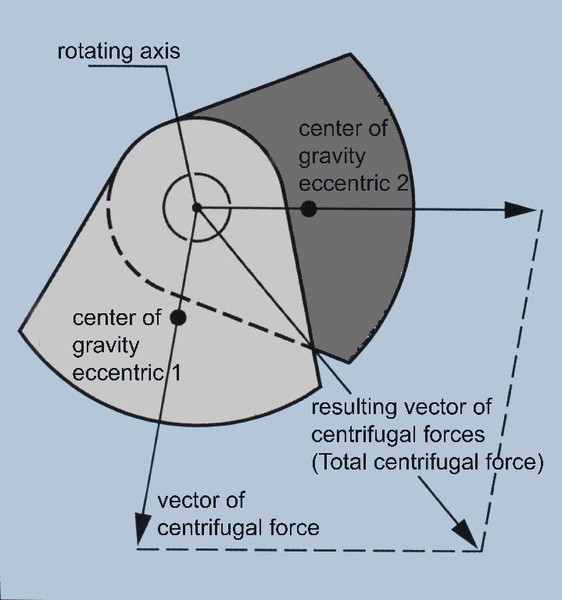

Each weight at rotation creates a centrifugal force vector whose direction is determined by the centre of motion (centre of rotor) and the centre of gravity. Since the total centrifugal force is determined by the resulting centrifugal force vectors, counterbalancing (twisting) of the discs is a way to increase or decrease the total centrifugal force (see fig. 2 and 4). External vibrators can create centrifugal forces up to 100 kN and more. To obtain great durability despite the rough operating conditions, external vibrators are equipped with vibration-proof, high temperature proof stator windings, special bearings with increased load capacity, and vibration-proof power cables.

Functionality of a Vibrator

The centrifugal forces, which the motor produces, set the vibrating equipment (table, shuttering, form, conveyor through) and the material (for example concrete) into vibration. The vibration is determined by the magnitude of the generated centrifugal force and the mass of the vibrating equipment, to which the vibrator is screwed down tightly and has to set into vibration.

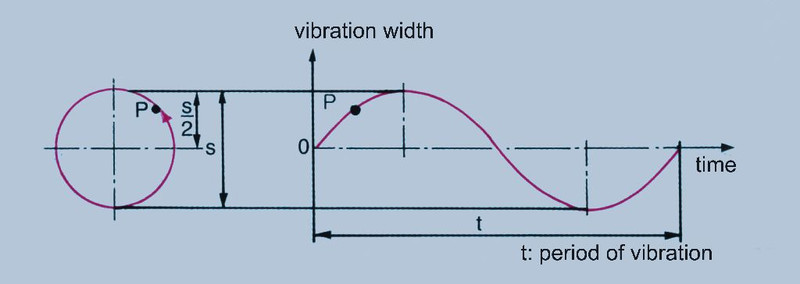

- Fig. 3 Movement of a point P at the vibrating equipment at a motor revolution

The vibration width s, the double amplitude, occurs at a specific point at the vibrating equipment during a motor revolution.

- Fig. 4: Formation of the resulting centrifugal forces

Modes of Vibration

Since the revolving weights create centrifugal forces in periodically changing directions, they evoke circular, linear or elliptic vibration. An external vibrator alone generates circular vibration, whereas two equal, parallel arranged and counter rotating vibrators create linear vibration.

- Circular Vibration

The vibrator moves the same mass radial to all directions; consequently the vibration width s is the same toward all directions, a circular vibration is created.

- Linear Vibration

Two equal, counter rotating external vibrators are attached parallel to each other. Due to synchronisation, the opposite forces cancel out each other and aligned forces add up. This creates linear vibration. At conveying e.g. two counter rotating vibrators create linear motion and thus allow the motion of bulk goods toward a specific direction.

The individual particles or pieces of material are repeatedly struck at a certain trajectory so that a chain of parabola-like micro-projectile motions takes place.

- Elliptic Vibration

A vibrator is mounted asymmetrically anywhere at a form, for instance at the end of a T beam. Because the vibrator has to move different masses at different directions, the vibration amplitude gets small at large mass and gets big at small mass. This changing vibration width creates elliptic vibration.

Fig. 5: Formation of circular vibration. Point p, as a part of the vibrating equipment, by constant changing centrifugal force direction, is put to circular vibration.

Fig. 5: Formation of circular vibration. Point p, as a part of the vibrating equipment, by constant changing centrifugal force direction, is put to circular vibration. Fig. 6: Formation of linear vibration. Point P, through the aligning forces, is brought to linear vibration.

Fig. 6: Formation of linear vibration. Point P, through the aligning forces, is brought to linear vibration. Fig. 7: Elliptic vibration. At the same the centrifugal forces Fc emerge different vibration widths s¬1 and s2, depending on the moving mass.

Fig. 7: Elliptic vibration. At the same the centrifugal forces Fc emerge different vibration widths s¬1 and s2, depending on the moving mass.

Types of Motors

Brecon external vibrators range from low frequency vibrators with 1000, 1500, 3000 vibrations per minute at a power frequency of 50 Hz to high frequency vibrators with 6000, or 12000 vibrations per minute at a power frequency of 200 Hz. The selection of external vibrators depends on the area of application (compacting, loosening, conveying), on the vibration equipment (rigidity, weight), and on the material is worked with (properties, weight).

A basic rule applies, that a vibrator at same centrifugal force with smaller vibration frequency creates a larger vibration amplitude and at the same centrifugal force with higher vibration frequency creates a smaller vibration amplitude. External vibrators with 1000 and 1500 vibrations per minute because of their comparative large vibration amplitude for example are used for sieving and for conveying of coarse-grained materials.

External vibrators with 3000 vibrations/minute deliver optimal performance at loosening and breaking up of fine-grained bulk materials. High frequency external vibrators with 6000 and 12000 vibrations per minute are excellent at compacting of fine-grained materials since their high frequency and small amplitude particularly strong activate micro-grained material. High frequency vibrators find most application at concrete compacting. External vibrators with 6000 vibrations/minute have a better depth effect and make less noise than vibrators with 12000 vibrations per minute.

| Types of motors | Electrical frequency | Number of pole pairs | Speed | Mechanical frequency |

|---|---|---|---|---|

| High frequency external vibrator (HF) | 200 Hz 200 Hz |

1 2 |

12000l/min 6000l/min |

200 Hz 100 Hz |

| Low frequency external vibrator (LF) | 50 Hz 50 Hz 50 Hz |

1 2 3 |

3000l/min 1500l/min 1000l/min |

50 Hz 25 Hz 16,66 Hz |

| Number of pole pairs | x 2 = Number of poles | |||

The Technology of External Vibrators: Areas of Application

- Compacting of concrete at large-scale forms

At this case of operation the vibration of the external vibrator is transmitted to the profile (vibrator beam) of the vibration equipment, then is passed on from the profile to the formwork facing and finally to the concrete.

- Compacting of material at small vibration tables

All kind of bulk materials can be compacted e.g. with a small vibration table, having mounted containers or moulds to the table. Two counter rotating external vibrators are mounted under the table top. They set the entire table to linear vibration.

Table 2: Overview of areas of application and fitting vibration frequency

Table 2: Overview of areas of application and fitting vibration frequency

- Loosening and breaking up of bulk materials in bunkers und silos

The to the silo attached external vibrator, brings the wall locally to vibration so that bulk material arches are caused to collapse.

- Conveying and sieving of bulk goods at vibrating conveyors and vibrating screens

External vibrators are used in conveyor technique for transport of bulk goods. Doing so, in majority of cases two (counter rotating) vibrators are mounted at a certain angle to the through conveyor.

- Loosening and breaking up of bulk materials in bunkers und silos

DE

DE ES

ES