General Information to the Performance of External Vibrators

Since compacting is one of the main areas of application of the external vibrator, the following general information primarily focuses this area. Special details for other areas of application are found at their particular chapters.

Transmission of Vibration

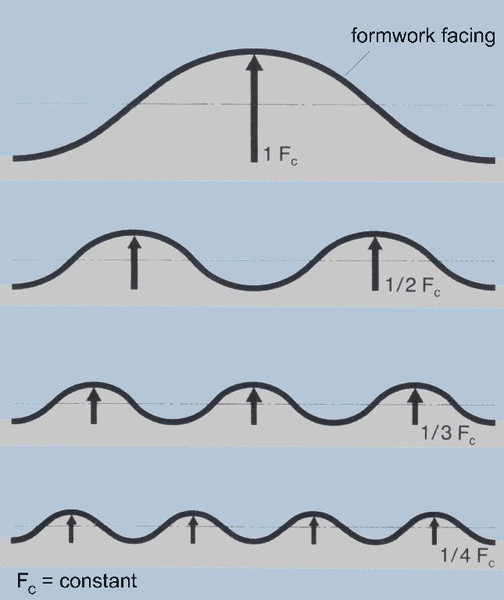

Great Attention has to be directed to the transition of the vibration, both at small vibration tables with one or two external vibrators as well as at large-scale shutterings for compaction with up to 50 external vibrators. At the production of precast concrete elements, the even distribution of the vibration, which creates even compacting, besides the acceleration and vibration time, is the most important criterion to obtain perfect surfaces and high density.It is essential to distribute the necessary centrifugal forces in such a way that they are transmitted to the vibration equipment at as many points as possible.

- Fig. 11: The effects of distribution of the centrifugal force on several transmis-sion points.

There they create so-called bending vibrations (bending of the beam). The separate external vibrators are mounted in such a way, that e.g. at large-scale moulds every external vibrator sets only its surrounding area to vibration, so that the vibration zones barely overlap by margins.

When at too labile forms resonances occur, appropriate measures e.g. additional reinforcers, change of mounting or change of frequency have to be taken to avoid breakage.

At correct installation of several external vibrators (at large-scale shutterings) and adequate rigidity of the form, the local load of the shuttering is decreased and it’s life time increased.

Mounting Location

Great attention has to be paid to the transmission of the bending vibration at choosing the transmission points.This is achieved best when already at building the vibration equipment adequate dimensioned, seamless reinforcement profiles are considered at the construction.

So-called vibrator beams serve as mounting locations and are responsible for the even distribution of the vibration.Wrong mounted external vibrators or inconvenient vibration equipment at compacting can create dead zones or areas with excessive vibration.

At small, rigid forms the external vibrators should also be mounted in such a way that they set the vibration equipment into even distributed vibration, i.e. they create all over the form about the same vibration amplitude.

Installation of Vibrators

To transmit the vibration of the vibrator as lossless as possible, at installation the following points have to be considered:

- Every external vibrator has to be bolted to a 15-20mm thick plate. This attachment plate has to be flat and thoroughly welded to the reinforcement profile.

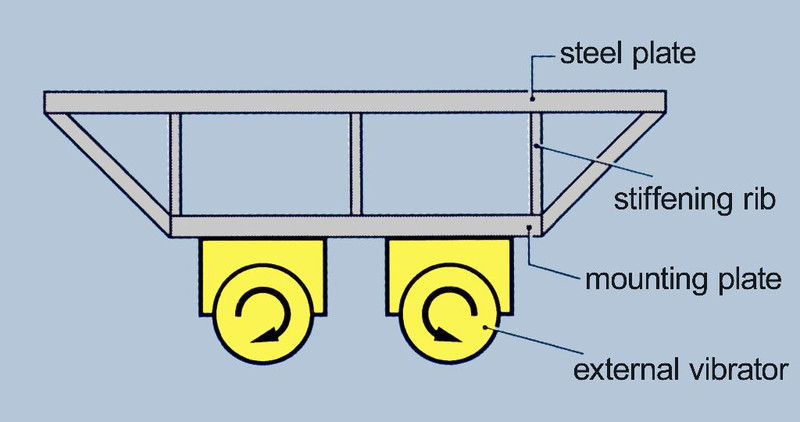

Fig. 12: A small vibration table with reinforcers

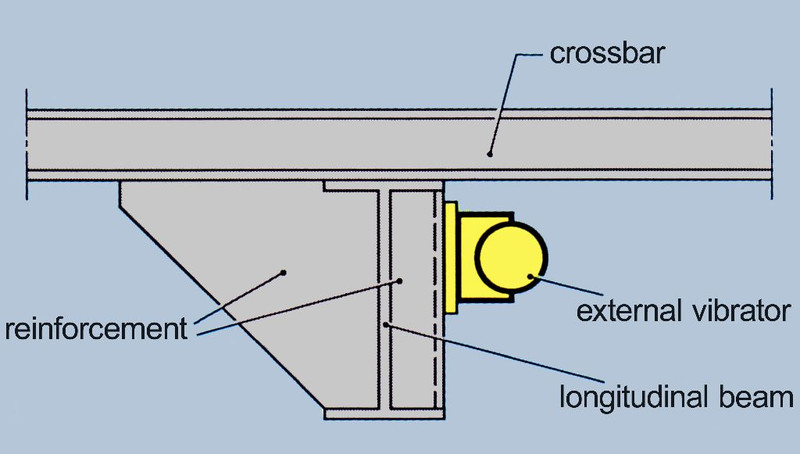

Fig.13: Vibrator arrangement with rigidity reinforcers

at a longitudinal beam of a vibration table

- When two counter rotating vibrators have to create linear vibration, the reinforcers between the vibrators have to be absolutely vibration rigid to make synchronization (absolute constant velocity) possible. This is obtained by adequate reinforcers. Figure 12 shows an example of this kind of reinforcement connections.

- To transmit the vibration loss-less to the desired place, deflection of the vibrator attachment parts (plate, beam) should be avoided. At high-frequency external vi-brators, which at high centrifugal forces create a vibration width of 0,4mm, a de-flection for instance of 0.1-0.2mm of the vibrator plate causes a loss of 25-50% of the vibration energy.

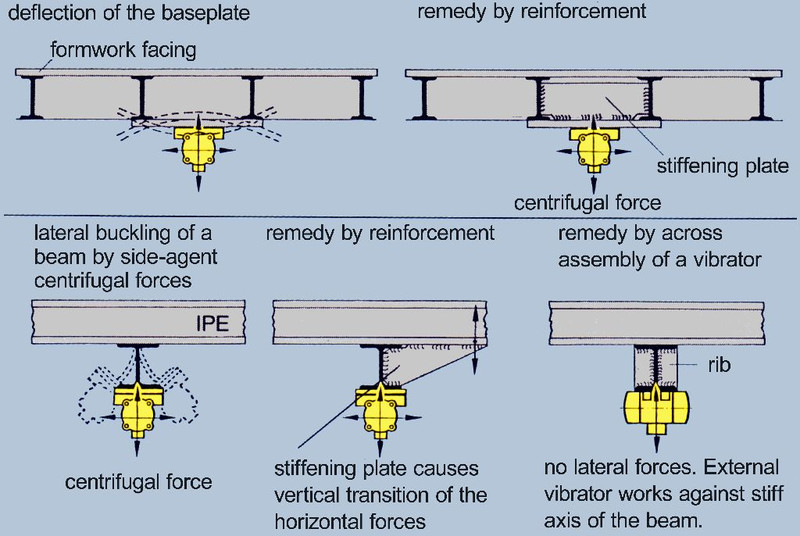

- Both of the main effective directions of the created centrifugal forces have to be considered. These are the perpendicular and parallel to the mounting plate acting forces whereas rectangular (to the two main forces) acting forces can cause weld-ing seam tears at the vibrator equipment. At such cases additional reinforcers (e.g. a junction plate) have to be welded to the reinforcement profile. Figure 14 shows possibilities to reinforce the mounting location.

- Fig. 14:Possible reinforcements of the mounting location of vibrators

- Steel sections have the function to distribute the vibration evenly. Vibrator beams with the steel sections HE-B 140 (IPB 140) qualify outstandingly for this task.

- The vibrators have to be mounted to reinforcement profiles and not directly to thin-walled construction parts like silo walls or shuttering plates of concrete element shutterings.

- Theexternal vibrators have to be bolted tightly to build a unit of the vibrator and the vibration equipment. To the installation of the vibrator, because of the great dynamic load, has to be given utmost care. Hardened and tempered steel bolts with the quality class 8.8 according to DIN931 and washers according to DIN125 have to be used. The flexibility of long steel bolts increases the vibration-proof at-tachment. The bolts have to be tightened with the prescribed torque. At installing with through bolts, locknuts or counter-nuts have to be used. The bolts, after a short period of operation, have to be re-tightened and be checked regularly for tightness. Loosening of bolted connections result in housing breakage, breakdown of the vibrator, and cracks at the shuttering. Insufficient fastening and loosening of the bolted connections is one of the most frequent reasons for errors.

Rigidity

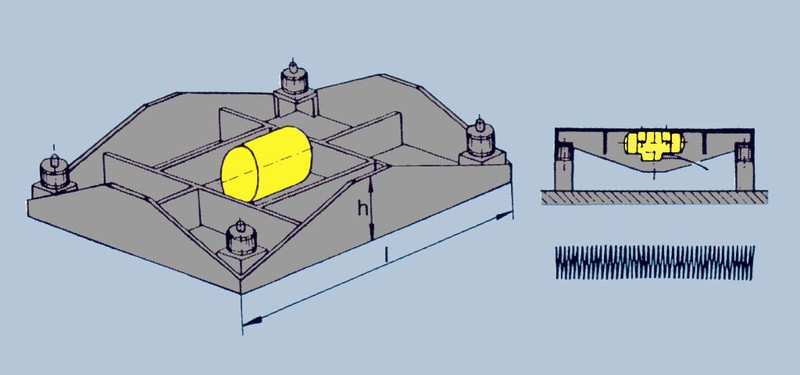

Vibration equipments are constructed right when the maximum degree of rigidity is reached at a low weight. Low weight and high rigidity are not contradictory requirements when the reinforcement is built with appropriate ribbings. The table construction in figure 15 has a high ribbing (trapezoidal) to the middle. The outcome of this type of reinforcement is high rigidity and even distribution of the vibration to the whole surface. The construction is vibration rigid when the height h averages 1/4 – 1/5 of the length l.

Fig.15: Right construction of a vibration table

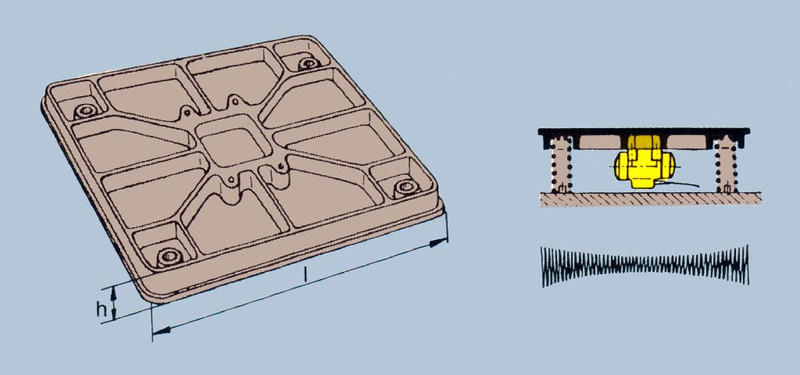

Fig.16: Wrong construction of a vibration table

The greater the centrifugal force the higher the ribbing has to be. The size of a vibrating table is 1x1m; the ribbing is 8mm thick. The weight of such a model is approx. 90 kg. The table construction of figure 16 in contrast throughout the table has a too thin ribbing at a ribbing thickness of 14-16mm.The table at the same size of 1x1m has a weight of 130kg. The result is uneven distribution of the vibration to the table surface. At soft-mounting, because of lack of rigidity, a ››flattering‹‹ appears at the outer area or at hard-mounting more deflection appears at the mid area. Vibration differences of up to 200% appear (amplitude blow-up).

The general requirements to a vibrator equipment are:

- high rigidity to obtain vibration stiffness

- even distribution of vibration and avoidance of amplitude blow-ups.

- Low weight to save vibration energy (Fc = m ⋅ a)

Vibration-isolated Mounting of the Vibration Equipment

Vibration equipments have to be mounted in such a way, that they can vibrate freely and no vibration is transmitted to the fundament and to the building.

For elastic-mounting rubber-metal-elements or in conveyor technique coil springs are used, too. The static load of the rubber-metal-elements should average 5-6kg/cm2 rubber surface. The dynamic load at short vibration periods e.g. at a shutterings of precast concrete parts can be disregarded. In practice rubber-metal-elements with a Shore-hardness of 55 Shore A have proved themselves for mounting of vibration equipment. It is crucial – especially for small vibration equipment – that rubbers with equal Shore hardness are used. 2 Gummifläche betragen. Die dynamische Belastung kann bei kurzen Rüttelzeiten, wie sie z.B. bei Schalungen von Betonfertigteilen üblich sind vernachlässigt werden. In der Praxis haben sich Gummi-Metall-Elemente mit einer Shore-Härte von 55 Shore A zur Lagerung von Rütteleinrichtungen bewährt. Wichtig ist, vor allem bei kleinen Rütteleinrichtungen, dass gleiche Shore-Härten verwendet werden.

In conveyor technique rubbers with Shore hardness of 40-45 Shore A are used.

40 Shore A e.g. means ››soft‹‹, and 75 Shore A means ››hard‹‹. The meaning of elastic mounting in no means should be underestimated since all the previous considerations apply only at a functioning vibration-isolation.

The elastic mounting is a basic requirement for the function of a vibration equipment.

Since at laying out of vibration equipments above all there is operated with approximate formulas and values, based on experience, the adjustment prior to commissioning is particularly important.

- current consumption

- vibration amplitud

- temperature

From the current consumption can be concluded the efficacy of the vibrator, type, and condition of the shuttering, it’s reinforcement, and as well as bolted and welded connections. By the vibration amplitude it is possible to find out, where reinforcers are necessary. The temperature (measured at the intermediate bearing) is an indicator of performance of the motor. A certain operating temperature (instruction manual) has not to be passed over.

Measurement of Current Consumption

At right construction of the vibration equipment and right dimensioned external vibrators, the current consumption of the external vibrator lies about at the same height as its nominal current. If the power consumption is way below the associated nominal current, the vibration equipment is too heavy. In this case the centrifugal force can be increased.Is the power consumption on the other hand greater than the nominal current, two factors could be the reason: The chosen centrifugal force is either too high. At this case either it has to be decreased or a smaller vibrator with smaller centrifugal force has to be mounted. Or the reason is lack of rigidity. At this case additional reinforcers have to be added.

Measurement of the Vibration Amplitude

For measurement of the vibration amplitude oscillographs qualify best. The vibration amplitude at all places of the equipment should be about the same. Table 3 lets detect if the intended vibration amplitude is reached.

| Synch-ronous speed 1/min | Vibration amplitude s in mms= (at values within parentheses there is a risk of form breakage and cracks) | |||||||||

| 750 | 6,5 | 9,7 | 12,9 | 16,2 | 19,5 | (25,9) | ||||

| 1000 | 3,6 | 5,5 | 7,3 | 9,1 | 10,9 | (14,6) | (18,2) | |||

| 1500 | 1,6 | 2,4 | 3,2 | 4,0 | 4,9 | (6,5) | (8,1) | (12,2) | (4,1) | |

| 3000 | 0,41 | 0,61 | 0,81 | 1,0 | 1,2 | 1,6 | 2,0 | (3,0) | (2,81) | |

| 3600 | 0,28 | 0,42 | 0,56 | 0,70 | 0,84 | 1,1 | 1,4 | (2,1) | 1,25 | |

| 5400 | 0,13 | 0,19 | 0,25 | 0,31 | 0,38 | 0,5 | 0,63 | 0,94 | 1,0 | 1,1 |

| 6000 | 0,1 | 0,15 | 0,2 | 0,25 | 0,3 | 0,4 | 0,5 | 0,76 | 0,45 | 0,78 |

| 9000 | 0,045 | 0,068 | 0,09 | 0,11 | 0,13 | 0,18 | 0,22 | 0,34 | 0,31 | 0,63 |

| 10800 | 0,03 | 0,047 | 0,06 | 0,078 | 0,094 | 0,125 | 0,156 | 0,234 | 0,253 | |

| 12000 | 0,038 | 0,05 | 0,063 | 0,076 | 0,1 | 0,127 | 0,19 | |||

| a* | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 150 | 200 | 500 |

|---|---|---|---|---|---|---|---|---|---|---|

Table 3: Detection of a and/or s at familiar synchronous speed

Further Measures

Further measures, which in practice can bring vibration outcome improvement:

- change of the direction of rotation

- change of location of installation (turning, moving)

- stiffening of the vibration equipment with additional reinforcement profiles

- the use of softer rubber-metal-elements (mounting)

DE

DE ES

ES