Modes of Operation and Choice of External Vibrators

External vibrators are also used for the collapse of bulk material arches in silos or other containers in which the bulk materials (e.g. sand, lime, cement, coal, cereals etc.) are kept before her further processing. The friction between the material particles is reduced by the vibration caused by the external vibrator and the adhesive forces between silo wall and bulk material are overcome.

There are two kinds of bulk material arches: bridge and shaft formation.

Bridge Formation

When the bulk material has become wedged in the trumpet hopper so that it is not able to flow off by itself any more and a so-called ››bulk bridge‹‹ is created. Internal friction, grain size, grain shape and humidity degree of the bulk material as well as the resistance between bulk material and funnel wall to slip, container and funnel form influence the bridging.

- Fig. 31: Loosening up of bulk material bridges in the silo

Shaft Formation

One speaks of a shaft formation when the adhesive powers of the bulk material at the container wall are so big, that the material at the wall builds up to the middle of the container, that only the material column standing over the leaving can be removed. Through this, the capacity of the silo permanently is reduced. The shaft formation is influenced by the surface characteristic of the inside wall of the container and the condition of the bulk material.

- Fig. 32: Preventing of shaft formations in the silo

Choice of External Vibrators

An exact calculation of the necessary centrifugal force when loosening and breaking up is not necessary at the individual case. There are a variety of empirical values which take into account the condition and the peculiarities of the bulk material and the silo, like grain size, grain shape and humidity degree of the bulk material, and size, contents, form, rigidity, and wall thickness of the trumpet hopper. At loosening and breaking up, external vibrators with 3000 vibrations/min for fine-grained bulk materials and with 1500 vibrations/min for coarse-grained bulk materials are used.

To avoid breaks at the silo walls and other damages at the silos, the centrifugal force and the on-time should be kept as low as possible.

|

|

Type |

Capacity |

Type of motor: 3000 vibrations/min |

|

|

small silo feeding hopper weighing container |

up to 5t |

1-3 kN centrifugal force per vibrator 1 vibrator |

|

|

slaked lime silo cement silo grain-/ fodder silo |

20-30 t |

3-10 kN centrifugal force per vibrator 1-2 vibrator

|

|

|

large silo bunker |

40-120 t |

7-14 kN centrifugal force per vibrator 1-3 vibrator |

Fastening of the External Vibrator

The fastening of the external vibrator at the silo is an important point, both for the function of the external vibrator and for the durability of the silo. The external vibrator may by no means be screwed directly to the bunker wall or to the run-out hopper. The material stressing at this place would be so big that the metal would tear. In addition, the influence of the external vibrator would be limited to an only very little area. To avoid these effects, a stiffening plate with a fastening facility for the vibrator must be attached at the silo.

Fig. 33: Example for the attachment of external vibrators at silos

Fig. 34: Example of the attachment of external vibrators to silos

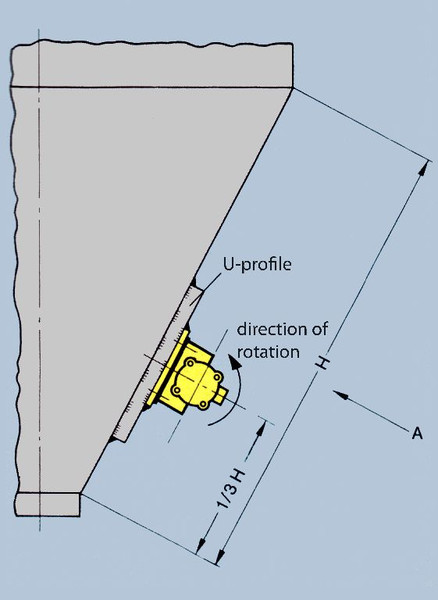

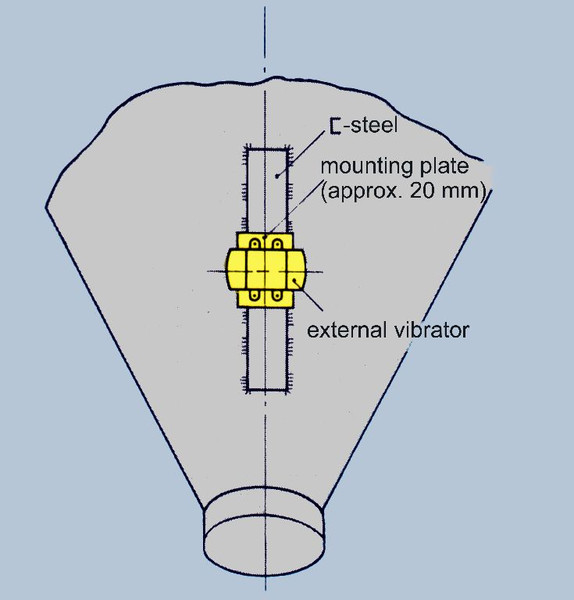

As effective and simple producible stiffening, welding (step welding) of U-shaped sections (see fig. 33 and 34) has proven itself.

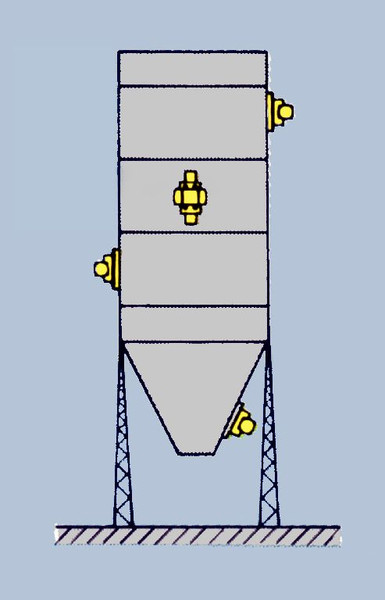

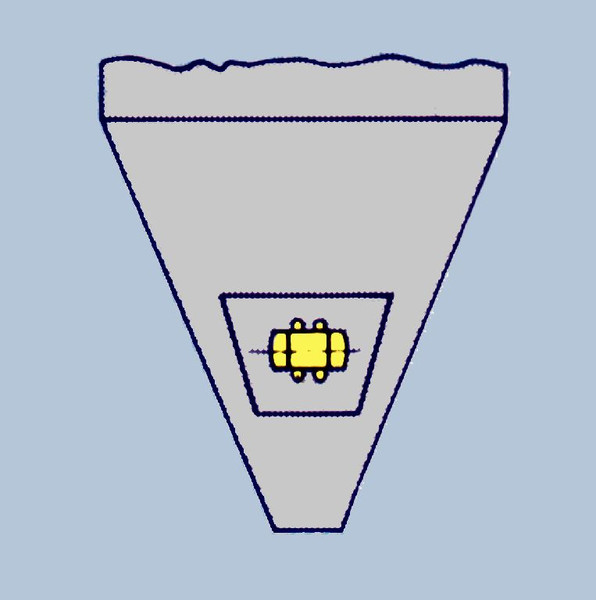

The U-shaped section should depending on size of the hopper be a U 80 - U 120 and have a length of approx. 400 mm - 2000 mm. It makes sense to lead the U-profile to the cross stay profile of the silo and to weld it to this profile. The external vibrator is attached vertically to the axis of the U-shaped section. The direction of rotation of the vibrator should be in such a way that, at a lateral view of the vibrator on the silo wall, the weights move from top to bottom. Since the vibrator works against the rigid axis of the U-profile, the silo wall and stiffening are spared and the by the external vibrator caused vibration is distributed better. Another possibility of stiffening of a container, silo or bunker with circular or rectangular crosscuts is welding on a 15 mm - 20 mm rigid plate (see fig. 35). This possibility is obvious, particularly when several little vibrators are attached to avoid shaft formations at the vertical part of the silo (see fig. 36).

Adjustment

If the external vibrators are chosen and the attachment places are defined, the external vibrators in any case should be adjusted to the silo. Thereto the function of the external vibrators is checked first. To check functionality of the exterior vibrators at the silo, there are two simple possibilities see Measurements and Adjustments: measuring the vibration breadth (amplitude) and measuring the current consumption of the external vibrator. When the vibration breadth (amplitude), measured at the external vibrator, is larger than 1 mm and the current consumption exceeds the given nominal value, the external vibrator puts the silo wall to too big vibrations. If the stiffening is sufficient, the cause only can lie in the too high adjusted centrifugal force.

- Fig. 35: Suggestions of attachment of external vibrators to silos

- Fig. 36: Suggestions of attachment of external vibrators to silos

Vibration of External Vibrators

The bolted connection at the mounting part of the external vibrators should be retightened shortly after putting the external vibrators into operation.

The external vibrators only may be started if the bulk material can drain of, since otherwise an unwanted compaction process occurs. To avoid compacting, a sure possibility is the coupling of the on/off switch of the vibrator with the closing of the silo. To avoid damages at the silo e.g. in case, a vibrator fastening would have been loosened by itself or welded seams and stiffenings would have been broken, every external vibrator should be safeguarded by a motor protection switch.

Application

Silos with bulk materials not in all cases serve only the storage but once in a while also are used for transport of bulk materials. At the shipment e.g. in silo wagons of the German Railways, the bulk material is compacted by the concussions during the transport and at high atmospheric humidity in addition can stick together. This leads at the final destination to expensive down times since the material must be made flow first with crowbars or similar tools. By use of external vibrators this problem is solved. A fastener is attached to the critical place at every wagon where the external vibrator is attached to support the outflow process at unloading.

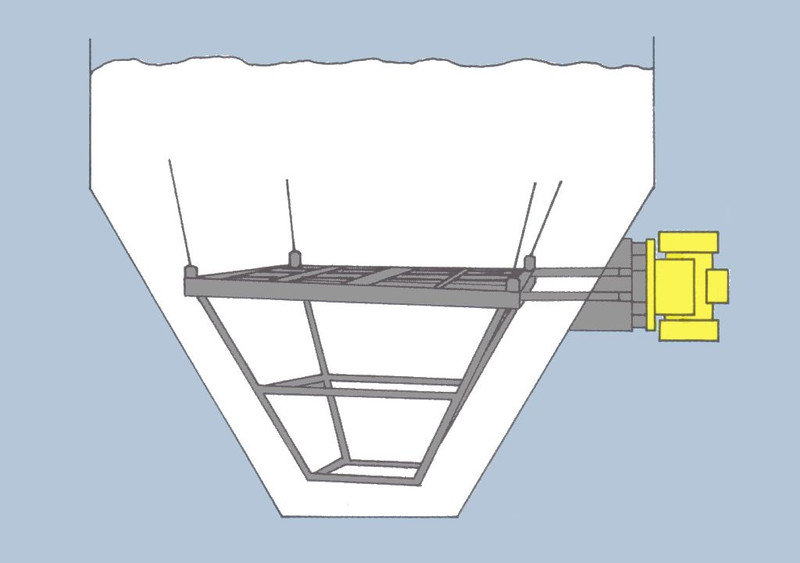

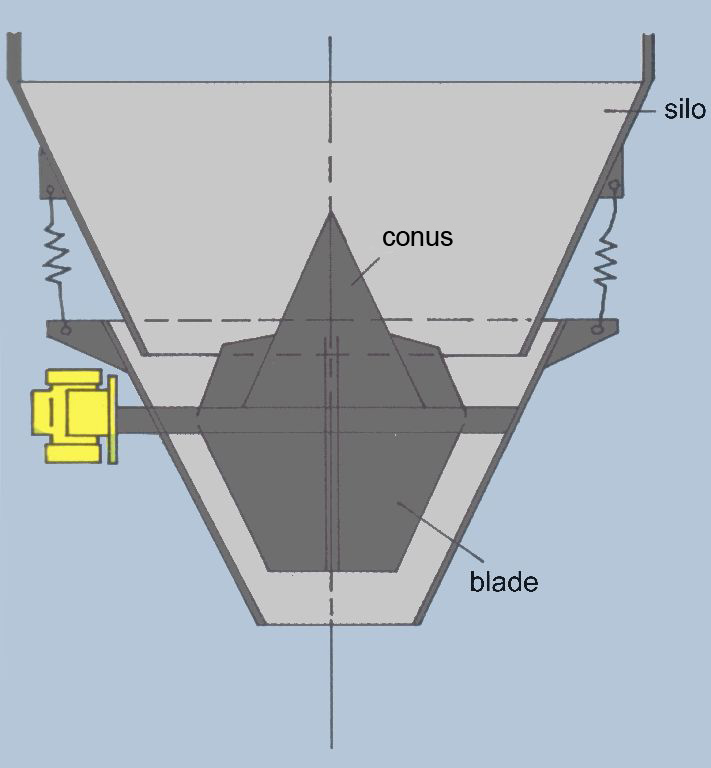

Fig. 39: A vibration basket at a silo

Fig. 40: Discharging vibration hopper

Another possibility of using external vibrators at silos is the use of discharging aids and discharging units. Discharging aids are discharging vibration baskets, vibration crosses or vibration grating surfaces. It is the advantage of this kind of breaking up that the external vibrator does not sit directly at the silo but at the vibration body.

Discharging units consist of a vibration body (cone, sieve, grating) and are set to vibration by an outside mounted external vibrator. The complete discharging unit attaches at the cone of the silo outlet and is hung up vibration isolated opposite the silo. The discharging units work as vibrating flow-out hoppers; they transfer the vibration to the bulk material which is caused by the external vibrator.

- Fig. 37: The external vibrator supports the flow out of the concrete distributor (company BUMAT)

- Fig. 38: The external vibrator loosens the bulk material and initiates the flow out of the silo.

DE

DE ES

ES